We are very serious about this topic and always offer and ensure quality work to reduce or eliminate customer’s pain areas.

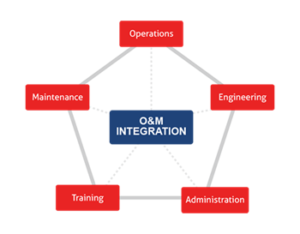

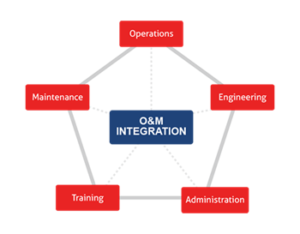

An Operations and Maintenance (O&M) program is a formulated plan of training, cleaning, work practices, and surveillance to maintain healthiness of systems installed inside the buildings or plant. The goal is to minimize the risk and cost of a running building or plant.

Operation is the performance of a practical work, or a state of working or being able to work, or a way or process that parts of a machine, system, or plant work together smoothly and safely to produce goods in accordance with the procedures.

Plant Operation is to operate and control of the plant ensuring efficient, safety, and reliable process operation.

Operation Readiness is the process of preparing the custodians of an asset under construction organisation to the client operation organisation, at the point of delivery and handover facilities, the client is fully prepared to assume ownership of the asset, accepts responsibility for performing the safe and efficient operation of that asset. The Operation Readiness is the management practices for performing pre-start-up reviews of new processes or processes that have been shut down for modification, and processes that have been administratively shut down for other reasons. These practices verify the operational readiness of a process and help to ensure that the process is safe to restart. Identifies organisational tasks, roles and responsibilities, assists with start-up and operations and maintenance, focuses on high priority risks, and analyses opportunities.

Operability is an ability that the process has the capacity and flexibility to achieve a range of operating conditions safely, reliably, profitably and with good dynamic performance and product quality. The Operability ensures to keep an equipment, a system or a unit and plant in a safe and reliable functioning condition, according to pre-defined operational requirements.

Maintenance is the activities that performs equipment or facilities to minimize the possibility of damage or the lowering of performance quality because of corrosion, contamination, or deterioration for the continuous operation.

Maintenance Readiness is a maintenance programmes that covers the maintenance planning and implementation for start-up and ongoing operations.

Maintainability is the ease and speed of the system restoring to the normal operational status, to prevent unexpected working condition, to maximise a product’s useful life, and to maximise efficiency, reliability, and safety operations. The Maintainability is the probability of performing a successful repair or replace using the prescribed practices and procedures for serviceability and reparability. This is similar to system reliability analysis except that the random variable of interest in maintainability analysis is time-to-repair rather than time-to-failure.